Vacuum systems with nanotechnology deposit thin layers of insulators and metals. The layers of metals are extremely thin, with sizes ranging from 5 to 250 nanometers. Different industries use these systems for various purposes, such as metal materials, lasers, and integrated circuits.

How does the system work?

First of all, the vacuum system requires pure layers of thin-film materials. They form the deposits that are suitable for nanotechnology. You will notice that these systems are extremely clean. This is because of nanotechnology's principle. They help to minimize the number of impure molecules in thin films introduced during deposition.

Suppose the film or the vacuum chamber has only one ounce of impurity or moisture. Nanotechnology will not work. It needs a clean environment for proper deposition. The problem with this system is you can't identify the type of impurity easily. It can be air molecules, moisture, or dirt lying on the vacuum pump's inner wall. Therefore, the system requires a clear path every time you want to deposit metals so that they travel from their source to the final sample without encountering any obstruction.

Ideally, you should use a vacuum chamber that provides high-yield thin film deposition to remove as much as 99.9999% air. This means the pump is literally free from impurities. That means there is probably one air molecule in 100 million present in the pump. How does the vacuum pump achieve this? First of all, it uses a sealed vacuum chamber.

If you look at a vacuum chamber inside a vacuum pump, it will look like a Clean Room. The Clean Room contains a metal deposition system where you can see an orange rubber ring. This is the vacuum gasket. It seals the chamber and doesn't allow outside air to enter the chamber. Once you close the gasket, you are ready to pump the chamber. Pumping the chamber doesn't mean metal deposition. It first cleans the chamber so that it can prepare for the nanotechnology to take effect.

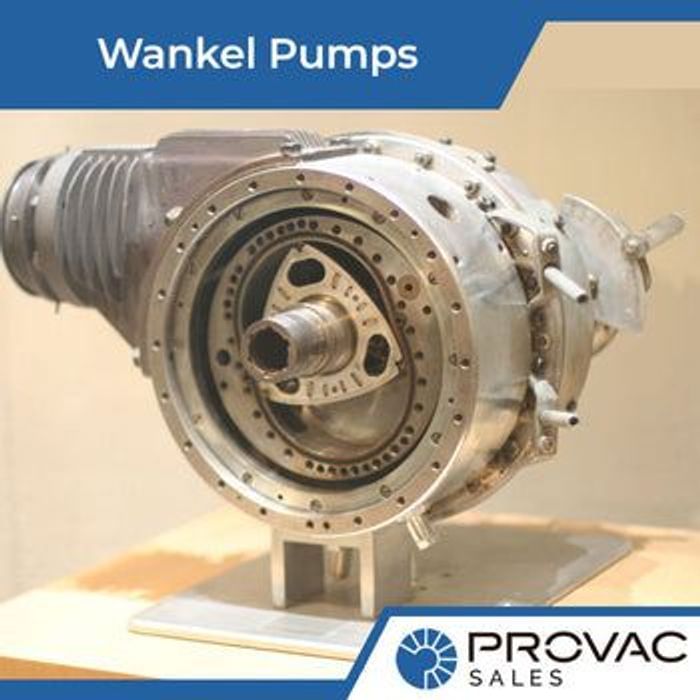

One of the most common pumps used in this process is a mechanical pump. Although various mechanical pumps are available in the market, they all serve one basic function: they can forcefully push air out of a vacuum chamber. This is crucial because it allows the vacuum pump to support nanotechnology.

The advantage of using mechanical pumps here is they push volumes of air out instead of sucking out the air. When the pumps push the air out, they clean the chamber thoroughly, thus providing the perfect ground for the vacuum pump to work. A rotary vane pump is the most useful for this purpose. The rotor used in this type of pump starts by pushing a small air volume through an outlet pipe. Every rotation pumps a higher volume of air out until it makes the chamber free from impurities.

A rotor vane pump operates at more than a thousand rpm. This means it can push air out from a chamber faster than any other type of mechanical pump, thus creating a low-pressure region ideal for nanotechnology. This low-pressure area causes the air in the chamber to move slowly toward the low-pressure region. The process is similar to wearing perfume. Suppose you spray perfume, and the molecules diffuse throughout the room. This means everyone else in the room can smell the perfume, especially if you wear it too much.

Now, imagine the same concept in vacuum systems. The pump keeps pushing air out of the vacuum chamber while the remaining air slowly diffuses to the low-pressure region. This results in low pressure in the chamber. The vacuum pump becomes less effective during this time but becomes efficient again once the nanotechnology kicks in.

Benefits of nanotechnology in vacuum pumps

Nanotechnology is now the buzzword in various industries like water purification, environmental sensors, environmental remediation, food packaging, battery storage, and renewable energy capture. Some of the biggest examples of vacuum pumps using nanotechnology are smart clothing with a layer of piezoelectric crystals in nanomaterials that allows the device to monitor your heartbeats and blood pressure.

The drug delivery industry also uses vacuum pumps with nanotechnology. They deploy liposomes to transdermal patches and nanoshells. Additionally, they also help in the development of various biocompatible nanomaterial prosthetic implants. The pump contains functionalized nanoparticles that experts use for imaging and treating various types of cancers.

Some of the most modern nano-enabled products contain silver nanoparticles because they have antimicrobial effects. This is because of the clean environment in which it is able to work.

Vacuum pumps with nanotechnology are a combination of many things. From keeping the chamber clean to delivering thin layers of metals during deposition, every step is crucial in this system. Honestly, it looks like a piece of art if you see the entire process and how systematically it works.