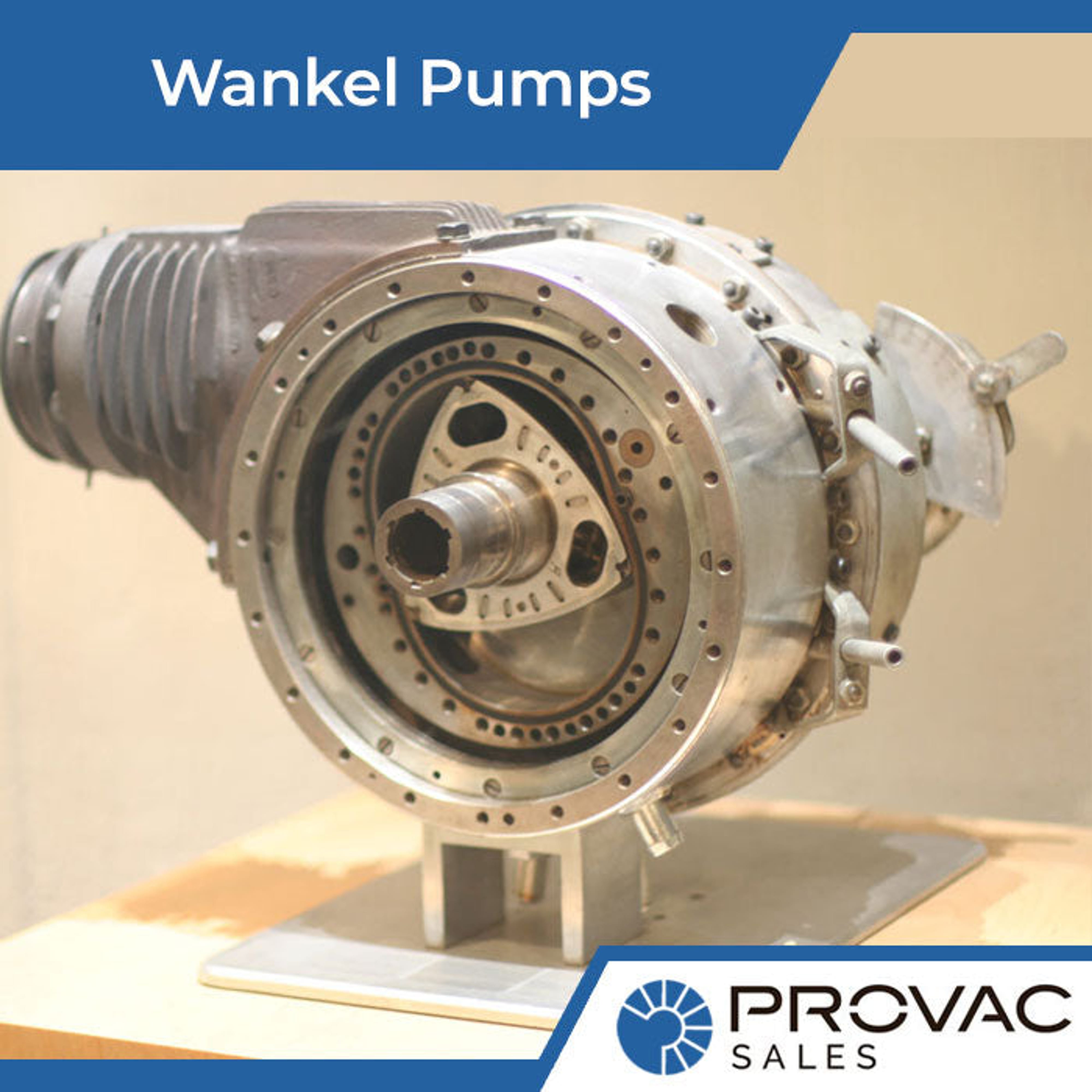

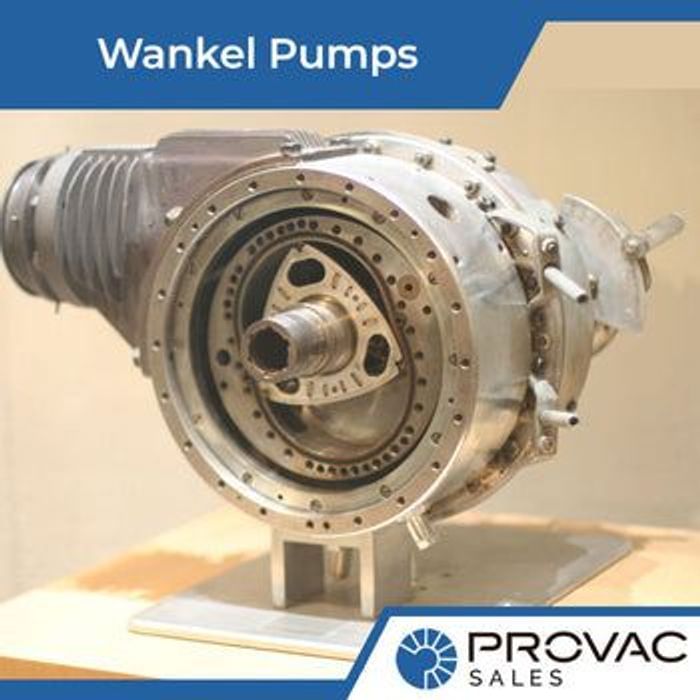

Image credit: https://commons.wikimedia.org/wiki/File:DrehkolbenmotorDKM54.JPG under CC BY-SA 3.0 - image resized without modifications

In the age of modern technology, machines and systems help make our daily lives run smoothly. The unassuming pump is an important component that usually doesn't get recognition across various industries. Pumps fulfill an indispensable role by ensuring the controlled flow of liquids or gases, from fueling our vehicles to driving industrial processes.

The Wankel pump boasts distinctive characteristics distinguishing it from traditional pumps, establishing its significance in various industries. In the upcoming sections, we will unravel the mysteries surrounding the Wankel pump, covering everything from its fundamental definition to its intricate inner workings.

What is a Wankel Pump?

Defining the Wankel Pump

A Wankel pump is a clever machine that enables precise fluid and gas control. Unlike traditional pumps with back-and-forth pistons, the Wankel pump takes a wholly distinctive approach, and that's why engineers and industry experts find it interesting.

How it works

Imagine a pump that operates elegantly, much like a spinning top. The inner workings of a Wankel pump showcase the power of innovative design. To understand how it works, envision a cylindrical chamber mounted eccentrically on a rotor, creating a trochoidal path as it rotates. Picture the fascinating process as this rotor gracefully moves within the chamber.

As it spins, the rotor the chamber's volume, leading to suction and discharge phases. These phases resemble the inhale and exhale of a living organism, efficiently pumping fluid or gas continuously and smoothly. This remarkable process ensures a consistent and efficient flow, making the Wankel pump an engineering masterpiece.

Applications of Wankel Pumps

Where Are They Used?

Wankel pumps have become essential tools in a wide range of industries. Their versatility and efficiency make them the preferred option for many applications that require precise control of fluids or gases. Let's examine some of the different sectors where Wankel pumps are vital:

Automotive Industry

In automobiles, Wankel pumps have a specific role in fuel delivery systems. Their capacity to sustain stable pressure and flow rates makes them well-suited for guaranteeing an efficient fuel supply in vehicles, ultimately improving engine performance and fuel economy.

Aerospace Engineering

In the aerospace sector, where reliability is non-negotiable, Wankel pumps find their use in aircraft fuel systems. Their compact design and capacity to manage high flow rates render them a favored choice for ensuring safe and consistent fuel delivery, even in extreme conditions.

Pharmaceutical Manufacturing

In pharmaceutical manufacturing, precision is important. Wankel pumps ensure the accurate dosing of fluids in the production of medicines, where even slight changes can have significant consequences.

Environmental Monitoring

Environmental organizations rely on Wankel pumps for air quality monitoring. These pumps' precision in delivering consistent flow rates is crucial for collecting precise data and safeguarding our environment.

Advantages Over Traditional Pumps

Wankel pumps have distinctive advantages compared to their traditional counterparts:

- Compact Design: Wankel pumps are renowned for their compact and lightweight design, making them ideal for installations with limited space.

- Smooth Operation: Their continuous, pulsation-free flow ensures precision and reliability in applications requiring consistent fluid or gas delivery.

- High Flow Rates: Wankel pumps handle high flow rates effortlessly, making them well-suited for applications demanding rapid fluid transfer.

- Minimal Maintenance: Their simple design minimizes wear and tear, reducing maintenance needs and downtime.

- Reduced Vibration: Compared to traditional reciprocating pumps, Wankel pumps generate less vibration, enhancing their durability and reliability.

These advantages and unique operational principles position Wankel pumps as valuable assets in various industries.

Limitations and Drawbacks - Are There Any Downsides?

While Wankel pumps offer various advantages, it's also crucial to acknowledge some of the challenges of their use. Let's break down these potential downsides:

- Seal Wear: Over time, the seals within a Wankel pump can experience wear and tear, which may result in leaks or reduced efficiency. Regular maintenance is needed to manage this issue.

- Complex Manufacturing: Producing Wankel pumps can be more intricate and, consequently, more costly than traditional pumps.

- Limited Suction Pressure: Wankel pumps may have limitations when handling high suction pressures, making them less suitable for specific high-pressure applications.

It's important to consider these drawbacks alongside their benefits when evaluating whether Wankel pumps is the right fit.

Recent Innovations and Developments - The Evolving World of Wankel Pumps

The field of Wankel pumps is always evolving and getting better. Experts, including engineers and scientists, continually make this technology more efficient and practical.

Lately, there have been some exciting improvements in Wankel pump technology. These changes might change how we use liquids and gases in various industries. Let's explore these exciting developments and what researchers are investigating right now:

- Material Innovations: Scientists are researching novel materials for pump parts to boost their durability and resistance to wear and tear. These materials may extend pump lifespans and reduce maintenance needs.

- Smart Pumping Systems: Incorporating sensors and intelligent controls transforms how Wankel pumps function. Real-time monitoring and adaptive control systems can enhance efficiency, making these pumps even more effective.

- Environmental Considerations: With a growing emphasis on sustainability, there's a rising interest in creating environmentally friendly Wankel Pump technologies that minimize energy usage and environmental impact.

- Miniaturization: Ongoing studies are focused on making Wankel pumps smaller, allowing their integration into more compact and portable devices in various industries.

These advancements show the versatility of Wankel pump technology and its capacity to impact shaping the future of fluid and gas management.

Conclusion

In conclusion, the universe of pumps is wide and diverse, each type catering to a unique purpose. The Wankel pump emerges as an engineering marvel, offering distinct advantages over traditional counterparts. From its sleek design to its seamless performance, it has found its utilization in various industries, including automotive, aerospace, pharmaceuticals, and environmental monitoring.

Whether refueling a vehicle or encountering a precision fluid dosing system in a pharmaceutical lab, spare a moment to acknowledge the often unsung hero—the Wankel pump. It serves as a testament to human ingenuity, constantly adapting to meet the expanding needs of modern industry. In the world of pumps, the Wankel pump radiates as a symbol of progress, innovation, and the limitless horizons of engineering.