The modern invention of sterilizing spices with vacuum pumps aims at making dry spice that’s great in flavor, while reducing/killing microbial content. Maintaining the aroma and color of the sterilized spice produced while killing the desired number of bacteria is a widespread and critical technical issue for the spice industry.

As an explicit technique for sterilizing spices using water vapor, a treatment whereby water vapor of at least 5 kg/cm^2 under standard pressure is applied, accompanied by being subjected to hot air for drying, and cold air to cool. Considering how the heating duration with water vapor will take around 5 to 45 minutes in this process, color tone and fragrance will deteriorate due to the sterilizing effect.

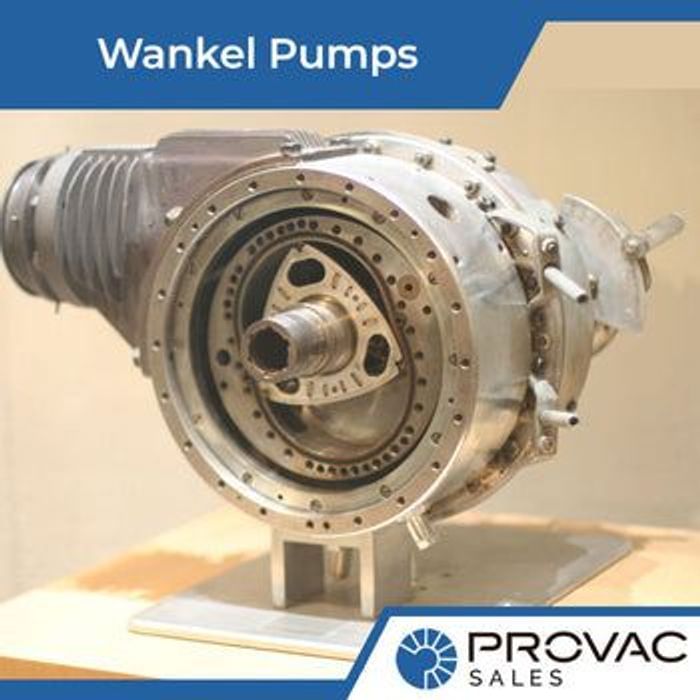

For this reason, a technique has been introduced where the raw spice is processed by putting it into an airtight casing, from which a vacuum pump is used to decompress the container to expel any air inside. Next, heated steam is directed into the casing to establish contact with the spice material, in a process referred to as the ‘steam sterilization method’. The sterilization prerequisites include a vacuum degree ranging from 2-20 kPa under absolute pressure, ideally 5-15 kPa; a steam heating condition ranging from 80-140°C, ideally ranging 95-135°C, and heat sterilized for 5-120 seconds. These sterilization prerequisites may be determined depending on the operating conditions of the sterilization equipment to be utilized, the kind of raw spice material, and the desired quality.

According to this technique, you can get spice that has been appropriately dried to the initial moisture content by successive aeration and vacuum drying, while at the same avoiding deterioration of the flavor and color thanks to vacuum steam sterilization. With this method, you can obtain dry spice that has diminished bacteria content, reduced moisture content, is microbially healthy, and has contained flavor and color modifications. Attaining these kinds of results has been problematic for the spice industry until recently.

The vacuum steam sterilization technique entails heated steam being added into a casing after all the air has been eliminated. The sterilization effect is attained within a short duration through steam treatment as the water vapor contacts and homogeneously penetrates the spice material. Per this technique, a low bacterial spice with minimal deterioration in flavor and color tone is obtainable. After steam sterilization, the airtight casing is decompressed and drawn to dispel the evaporated water and allow the sterilized spice to dry and concurrently cool. This is thanks to the latent evaporation heat in a process referred to as vacuum drying. If you are looking to increase the effect that the vacuum drying process may have on the spice, you can move it to a separate vacuum cooling dryer to perform the drying.

After performing sterilization heat treatment, the next phase entails expelling water vapor from inside the airtight casing, from where vacuum drying will be conducted. The interior of the airtight container will be subjected to decompression again using a vacuum pump. The higher the vacuum degree in this particular vacuum drying stage, the better. It is noted that the greater the vacuum degree subjected in the container, the more difficult it will be to dispel the gas. So, upon reaching 5-20 kPa under absolute pressure, you should discontinue the process and proceed to aeration drying. You should view this from the angle of how much spice you want to produce. The equipment utilized for the decreased pressure steam sterilization and vacuum drying process is not exactly constrained.

After conducting vacuum steam sterilization and vacuum drying as explained above, air drying is subsequently done. The prerequisites for drying at this step are determined depending on the moisture content to be decreased, the kind of spice, the duration of treatment, and airflow amount. However, the air temperature to be aerated is chosen according to the standard room temperature which is around 80°C. In case the temperature of air subject to aeration is exceedingly high, the spice materials will get browned, burnt, and change in flavor/fragrance, and the goal of using this method won’t be attained. The ideal temperature of air should be between 40 and 75°C. With regard to the quality of spice you are going for, the spice must attain a predetermined moisture concentration. The aeration process is ideally done for around 15 to 300 minutes at a standard room temp after the vacuum drying step.

Using vacuum pumps to sterilize spices has proven to kill microorganisms of all types. This way, you are guaranteed to get spices that are great in terms of flavor and color.