Zinc is one of the most essential metallic elements used in metal coatings, medication, makeup, pigments, and skincare products. It is used primarily for the following purposes:

- Making brass

- Construction materials

- Anti-corrosion coating on brass and steel

- Pharmaceuticals and cosmetics

- Die casting

Mining zinc isn’t an easy process. It involves various methods, such as traditional underground mining techniques and open-pit mining. Open-pit mining is suitable for oxidized zinc ore bodies that stick close to the Earth’s surface. On the other hand, the traditional method of extracting zinc is cut and fill stopping where you need to dig tunnels up to a specific depth and then branch away to carry as much zinc as possible.

According to geologists, almost 80% of the zinc that people extract is from the Earth’s surface with the majority of the mining taking place through the open-pit method. One of the most essential machines used in this process is a vacuum pump.

Vacuum pumps for mining zinc

The open-pit method involves using liquid pressure to suck the surplus air from the area you are planning to mine to produce high-quality zinc that hardly contains any contaminants. A vacuum pump has the precise mechanism required for this technique. In this system, the pump significantly reduces the plot’s liquid pressure, followed by attaining the pressure needed to evacuate the surplus air and eliminate the unwanted elements from zinc ores.

Usually, the cut and fill stopping method involves working on areas where you are confident of not finding contaminants. However, those are rare cases, and you may not find the technique effective enough to extract a high quantity of zinc. Instead, the open-pit method uses vacuum pumps tactfully to reduce the liquid’s boiling point, and thus, extract a large chunk of zinc that doesn’t contain unwanted elements.

How do you know whether the vacuum pump you are planning to use for mining zinc is effective or not? There are two factors that you need to consider: throughput and pumping speed. The more the throughput and pumping speed, the faster the pump can extract zinc. You may also consider looking at the pump’s suction capacity to compare how efficient it is to extract zinc from underground ores.

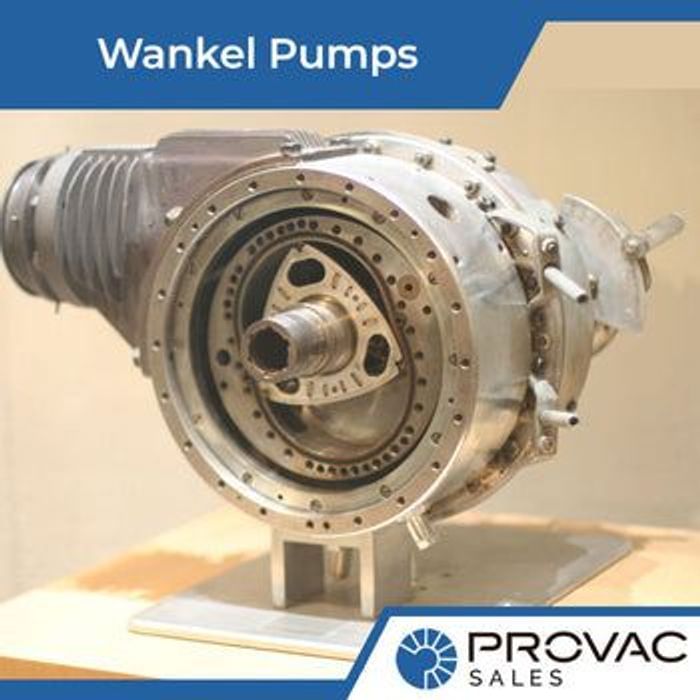

Mechanism of vacuum pumps

The working mechanism of a vacuum pump is ideal for mining zinc since the method involves extracting the element in its purest form. A vacuum pump first eliminates air using a closed system with the help of its suction pressure. This would slowly and steadily reduce the air’s density in the space where you are mining, thus creating a vacuum. Once the pump creates a vacuum in the closed system, it uses its mechanical energy and revolving shaft to make the most of its pneumatic power.

On activating the pneumatic power, the pump’s inside force levels with its preserved volume that slowly reduces over time. This preserved volume reduces to a level below the average volume of the environment, thus helping the pump generate energy that can use the suction pressure to extract zinc from ores efficiently.

Why use vacuum pumps for zinc mining?

Although there are various types of pumps available, why do miners use vacuum pumps to extract zinc? According to experts, this pump has all the features required to extract high-quality without spending too much time and energy. Here are a few more reasons why vacuum pumps are essential zinc mining:

They can successfully implement the suction pressure required to produce zinc. Additionally, they can use the same pressure to move unwanted materials from the campsite so that you can extract the best quality zinc available.

Vacuum pumps have spill-avoidance chambers that ensure low wastage. In fact, they have odor-controlling capacity so that you can carry zinc safely without spreading its pungent smell.

Since these pumps use vacuum and suction pressure, there is hardly any chance of the extracted zinc to mix with poisonous waste from the ores. They can remove waste materials within a few seconds and also get rid of them fast to prevent drains from blocking.

Types of vacuum pumps

- Positive displacement

- Moment transfer

- Regenerative

- Entrapment pump

A positive displacement pump expands the ore’s cavity, thus allowing the pump to suck a huge quantity of zinc from it without wasting time. It is ideal for areas where you require a low vacuum pressure to extract zinc.

Momentum transfer pumps are the fastest in the industry and are appropriate for areas where you need high vacuum pressure. However, they work best with displacement pumps.

A regenerative pump implements vortex performance and a combination of turbopump and centrifugal force to produce zinc.

An entrapment pump uses cold temperature to produce a hard residue of zinc. It’s suitable for extracting zinc that other vacuum pumps can’t.

In addition to mining zinc, vacuum pumps are also essential in the manufacturing of semiconductor processing, electric lamps, dry etching, hydraulic brakes, and throttle drivers.