Dirty and Noisy

Rotary vane pumps, which are known for their deep ultimate base pressures and economical service, have a rotating cylinder along with sliding vanes that are away from the middle of a cylindrical chamber. When vanes move past the inlet, the volume expands, and gas moves in. As the vanes continue to rotate, the inlet is eventually closed. From there, the gas decreases in volume, leading to an increase in pressure until the outlet opens again, which is when the gas is able to escape the chamber.

Since vane pumps are powered by a rotating rotor and feature numerous moving parts, they can make quite a bit of noise. At the point when they hit minimum pressure levels, the pumps may also rattle. In most cases, these pumps are dirty. The space between the pump chamber walls and the vanes is sealed tight so that there is a layer of oil. This oil can transfer from the pump into the sample chamber unless preventative steps are taken. It's also common for the pump to leak over time. A blown seal could cause even worse problems, such as an oil spill that can be sticky and difficult to clean up.

Vane pumps are durable and affordably priced. There's a reason why these pumps can be found in physics departments across the globe. They're simple to maintain, especially if you work in the field of experimental physics. If repair work is needed, an experienced technician should be able to handle that on-site.

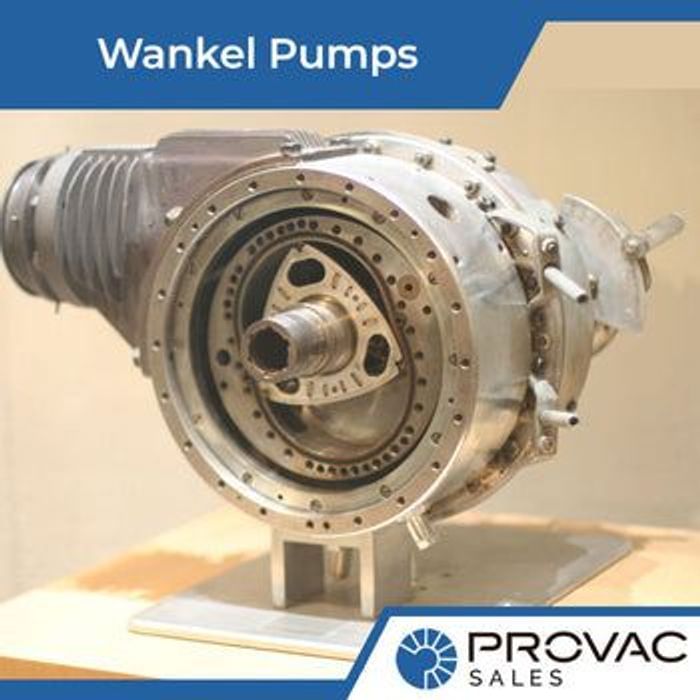

Turbomolecular pumps vary in design but most modern units are oil-free and require little maintenance in between bearing changes. These pumps essentially operate in the same way that a small jet engine would. They feature an assortment of rotating turbine blades which rapidly rotate, causing gas to be transferred from the inlet of the pump to the outlet. Pumps rotate at speeds up to 90,000 RPM.

Why do turbo pumps make so much noise?

One of the reasons turbo pumps become noisy is because of the bearings. When the bearing is coming to the end of its life the turbo pump will start to emit a high-pitched whining noise. This indicates that the bearing is on its way to failure and it should be replaced.

Clean and Quiet

Dry scroll pumps, especially modern designed scroll pumps have extremely low decibel ratings during normal operation. Dry scroll feature an interlocking set of spirals rather than a rotating shaft that has sliding vanes. Because of the spiral-shaped design, the pumps are much more efficient. This means they can produce a seal without oil, which is why they tend to be clean. They're not actually very noisy either. They will make rattling noises when in use, but they don't produce the loud sounds that rotary vane pumps make. Of course, they're far more costly than rotary pumps, and they're not able to go beyond millitorr pressures. Because of this, these pumps are used where you may

Cryo pumps, which are often used for high-vacuum applications, are certainly cleaner than turbo pumps. However, they can still be described as noisy. These pumps channel cold to pump gas. Gas circulates, where it is liquified. The gas is then used to cool an assembly. From there, the assembly sticks to the vacuum chamber. In some cases, it may be coated with a material, like charcoal, to increase the total surface area. If the gas has a boiling point that is above the temperature of the cooling liquid, it will freeze to the surface, which will cause the pressure inside the chamber to be lowered.

These pumps tend to make a lot of noise because they are used in conjunction with a compressor so that gas can be liquefied easily. Some pumps use helium gas to rapidly cool down the internal assembly. These pumps can be so loud that they can be heard from a distance. On the plus side, if you don't hear any sort of noise, you'll know that the pump is malfunctioning.

In spite of all this noise, these pumps tend to stay very clean, since there's no way for dirt to enter the vacuum system. These pumps are extremely costly, and the compressor and pump aren't the only expense. Obtaining the helium gas for the pump can also be extremely expensive.