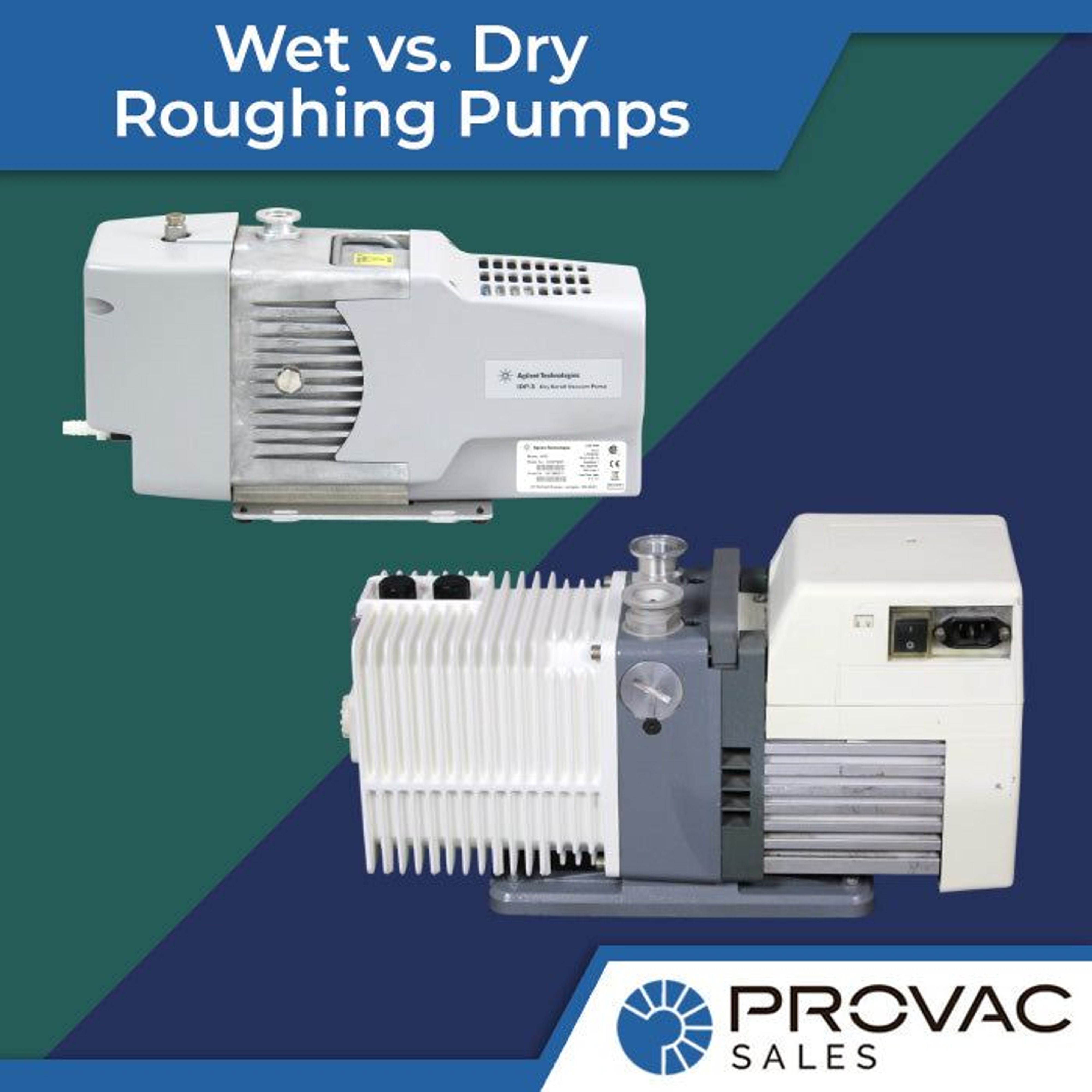

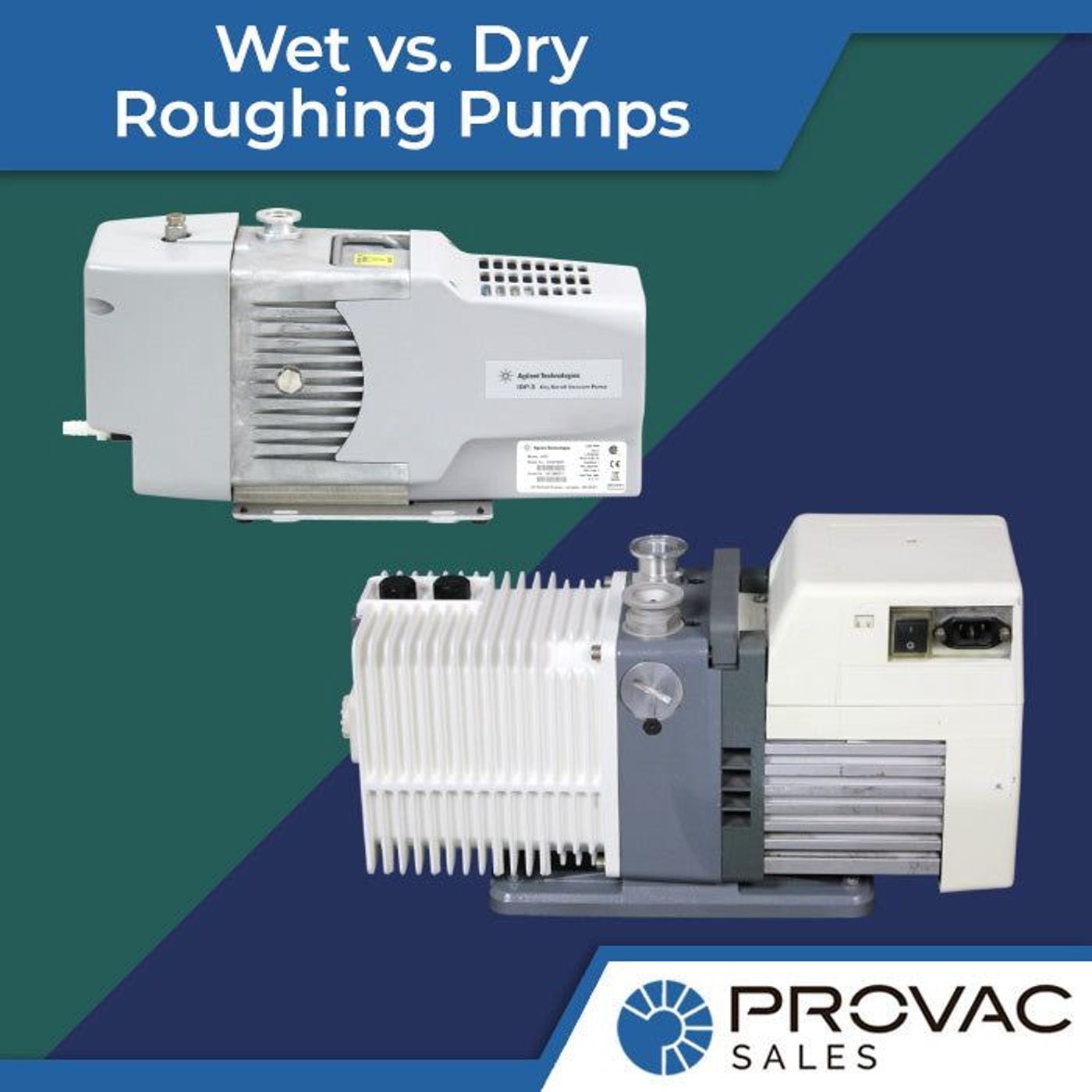

The new trend in roughing pumps for the last 20 years has been to move from “wet” oil sealed piston and rotary vane pumps to “dry” oil-free screw, hook and claw, diaphragm, and scroll pumps. Many customers prefer to not use oil due to the perceived mess oil changes can cause, but there are upsides and downsides to both types of pumps. Reviewing the benefits and disadvantages for both types of vacuum pumps can give you better insight into which type would work best for your application:

Dry Pumps

Benefits:

No oil changes

Disadvantages:

Higher purchase price

Higher cost to rebuild

More propensity for major hard part damage

More sensitive to contamination (process cannot be run through many types)

More sensitive to moisture

Wet Pumps

Benefits:

Average longer lifespan in-between rebuilds

Lower purchase price cost

Lower cost to rebuild

More preventative maintenance that can be done to increase lifespan between rebuilds

Typically quieter than dry pumps

More resilient to contamination

More resilient to moisture

Disadvantages:

Oil must be changed and can be “messy”

Possibility of back-streamed oil into inlet side of pump

Have questions? Contact us today for information.