Before vacuum lamination, you only had two options to design your car's exterior: press lamination, or adhesive lamination. Although they were widely popular, there were several downsides to these methods. For example, adhesive lamination involves using the most potent adhesive available on a sticker. This sticker went on the car to give it the graphical look the client wanted. Things have changed now. Although both adhesive and press lamination still exist, they have made way for vacuum lamination.

Vacuum lamination on automobiles

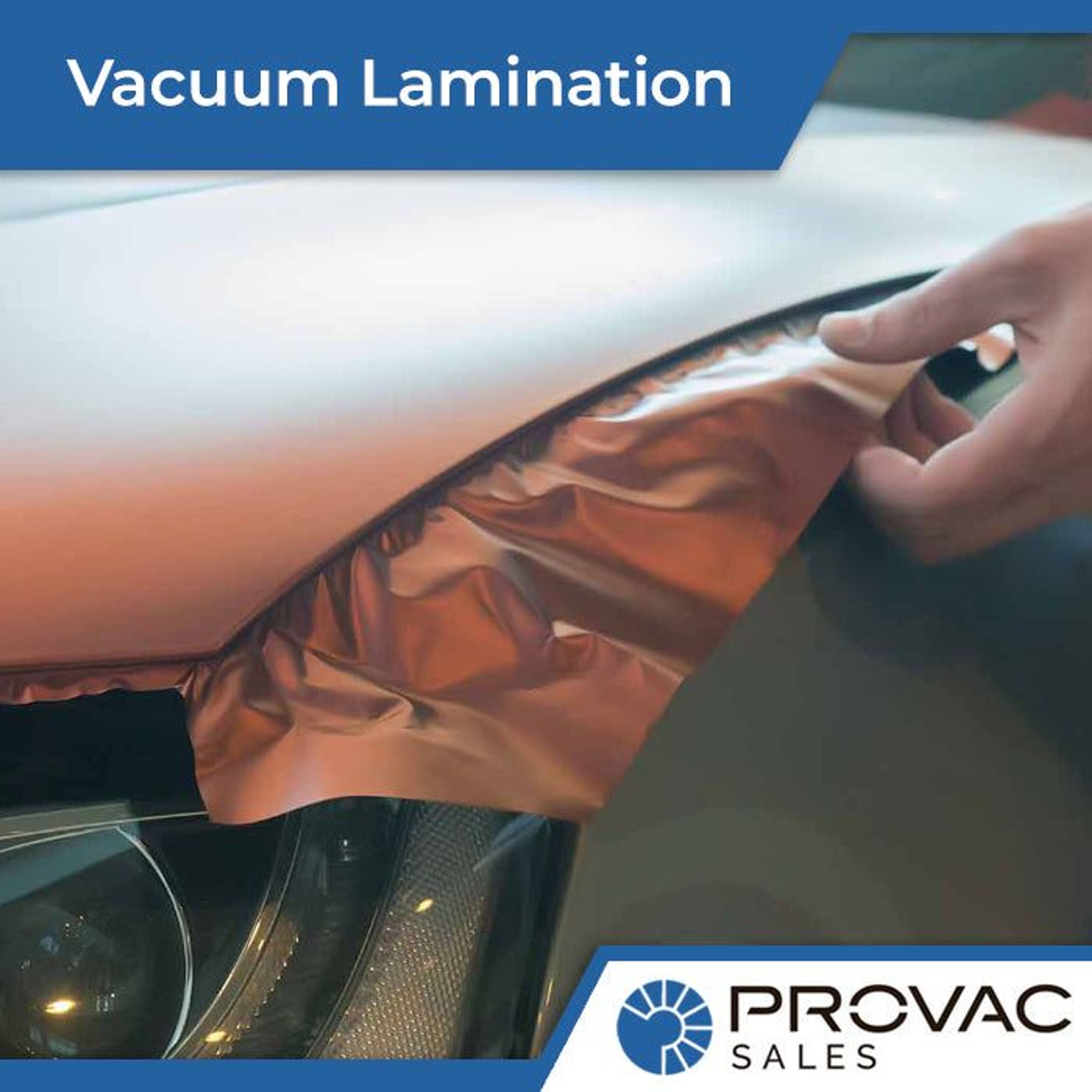

Vacuum lamination is an almost permanent form of graphic design on your car. Like tattoos, they stay on your car unless you use a removal technique to get rid of the graphic. Vacuum lamination involves using a laminating film material on your car's exterior or interior to give it a unique look.

Here is the vacuum lamination process that the experts follow:

1. Film selection

The process starts by selecting the type and color of the film you want. Usually, most car owners prefer a single sheet because it maintains the consistency of the color. However, you may select contrasting colors also. For example, one color for the bonnet and back, while another color for the sides and top. Compare the price of the lamination films also. It is wise to buy an expensive film for this method because it responds well to the lamination process.

2. Diaphragm lamination

Once you select the film, the professionals will inject compressed air into a diaphragm, or as the experts call it, rubber balloon. The rubber balloon will expand as air fills in from the inside. The expansion of the diaphragm presses it to the film. Mild pressure is ideal in this situation as it allows the technician to handle fragile materials, such as oil or water easily. Diaphragm lamination is also best for comparatively thinner films and narrow patterns. It maneuvers on your car's complicated parts like handles and headlights easily.

3. Rubber vacuum lamination

This vacuum lamination method is ideal for producing luxurious dashboards, armrests, side panels, trims, wood panels, and covers. Unlike diaphragm lamination that is mostly used on the exterior, this lamination method works on the interior of your car. The heated vacuum membrane machine presses the rubber film first. It then wraps the parts you want to laminate in your vehicle.

Most of the rubber vacuum laminators come with advanced heating technologies, equipped with automatic production processes, straightforward monitoring systems, forced-air convection, and IR lamps. These are essential to meet the quality standards of the automotive industry. The machine also offers optimal conditions to provide heat-resistant high-strength bonding for 3D designs.

Some of the most common applications of rubber vacuum lamination are:

- Covering car dashboards – this vacuum lamination method can provide 3D pressing and cover on your dashboard.

- Wood veneering – you can get high-strength veneering of your car's inner panels and trims and give them a wooden look with the vacuum films.

- Covers and side panels – vacuum lamination and pressing the side panels give them a leathery finish that makes your car look luxurious.

4. Flattening

Once the technician finishes the lamination process, he will flatten the surface to avoid any bumps on the sides, front, back, or top. It gives a nice, smooth finish to the lamination, giving it a matte look.

Benefits of vacuum lamination for your car

Since this method uses vacuum, you don’t have to worry about getting sticker stains out. The downside of adhesive lamination is car owners have to pay a significant amount of money to get the adhesives removed from their cars if they decide to do away with the graphic stickers. This is often the case when car owners decide to sell their car in a couple of years. The new owner may not want to buy a car with graphic art all around.

With vacuum lamination, you don’t have such drawbacks. As the name suggests, the method depends entirely on vacuum. The film that sticks on your can be removed quickly. It hardly takes an hour to get rid of the film if you don’t want it on your car.

Apart from the quick removal advantage, another reason why vacuum lamination is ideal for vehicles is it doesn’t involve any air bubbles. Unlike stickers where there are high chances of bubbles left inside the film, vacuum lamination goes a step further to flatten the film on the surface to eliminate bubbles. This makes the graphic design look better on your car.

The vacuum lamination method is one for the future. It provides a smoother and long-lasting finish, even though you can get rid of the graphic quickly. Try it on your car and see how wonderful it looks.