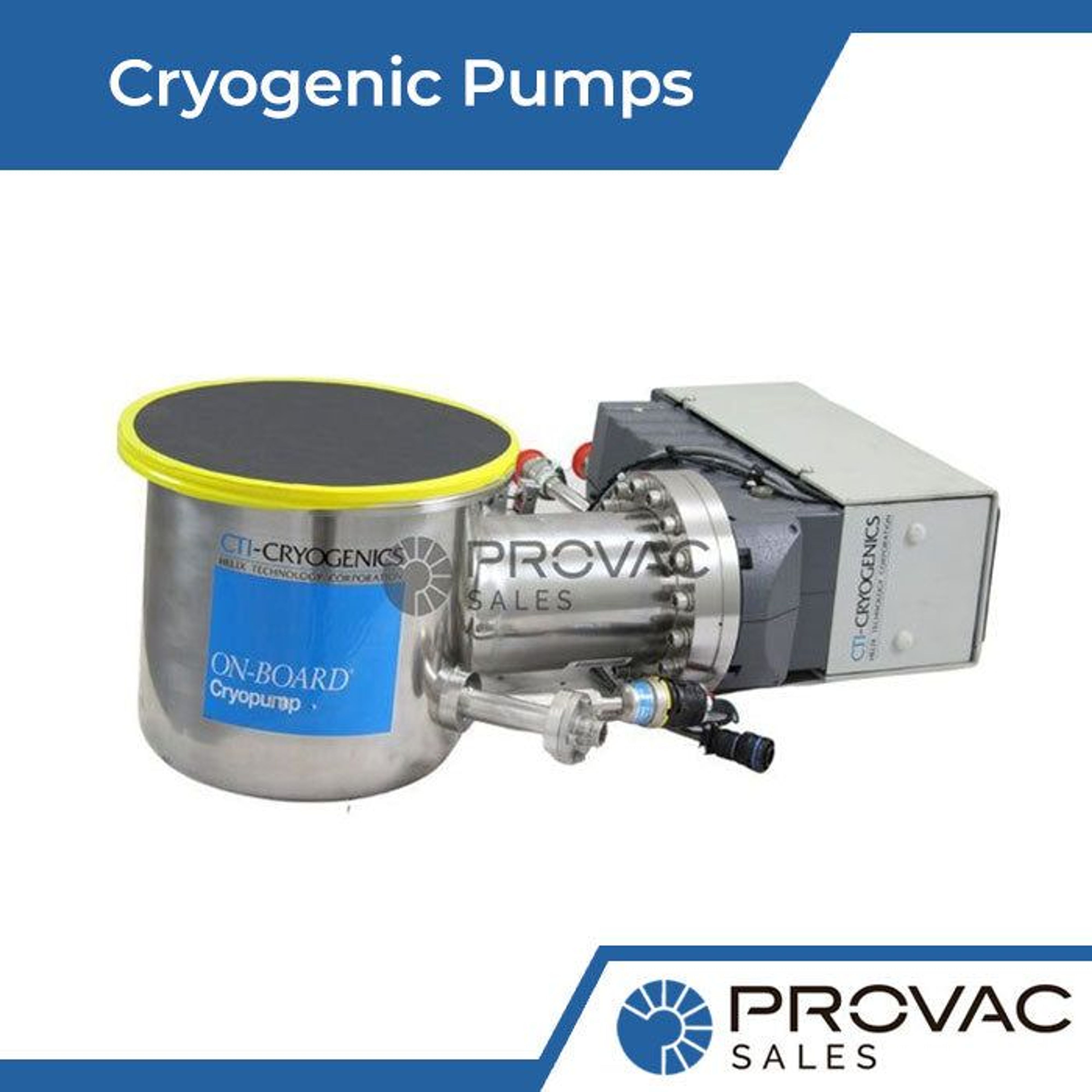

Have you ever considered the role of a basic device such as a pump in driving groundbreaking advancements across sectors such as medicine, aerospace, and energy? Consider the unique world of cryogenic pumps, where the ordinary becomes exceptional. Imagine a machine with the capability to manage substances at temperatures significantly below freezing, unveiling possibilities once perceived as unattainable.

A cryogenic pump, built purposely for the most frigid environments, typically functioning at temperatures below -150°C (-238°F), is a perfect example. However, it is not solely the sub-zero conditions that distinguish cryogenic pumps; it is their extraordinary capacity to manipulate substances within these difficult conditions.

At its core, cryogenic pumps excel in the transport, compression, and precise control of cryogenic fluids—substances cooled to remarkably low temperatures. These pumps support a wide range of important tasks, from preserving crucial biological samples in labs to helping launch rockets into space.

How Does a Cryogenic Pump Work?

At their core, these pumps are intricate devices crafted to handle substances at temperatures that would freeze most equipment in its tracks.

The key to the functioning of cryogenic pumps lies in their close affinity with low temperatures. Just as your car engine relies on gasoline for power, cryogenic pumps depend on extreme cold to perform their wonders. But why? What is it about the cold that enhances their effectiveness?

A cryogenic pump adeptly manipulates ultra-cold substances, enabling precise control and transportation. Even though it's not filled with technical terms, this comparison helps us understand how cryogenic pumps deal with very cold temperatures.

Types of Cryogenic Pumps

Cryogenic pumps come in various types to suit different needs and tasks. Before we explore their fascinating applications, let's learn about these pump categories.

Cryogenic pumps can be classified into two primary groups: centrifugal and positive displacement pumps, each characterized by their unique traits and strengths.

Centrifugal Pumps: Imagine centrifugal pumps as the sprinters of the cryogenic world. They work by spinning an impeller to create a fast flow of icy-cold fluid. This quick movement lets them move lots of fluid quickly but not over long distances.

Positive Displacement Pumps: Now, positive displacement cryogenic pumps are more like marathon runners. They use a different method, like filling and emptying small chambers, to push cryogenic fluids. This way, they have precise control and can handle high-pressure jobs.

Applications

Now that we've sorted out the differences between centrifugal and positive displacement cryogenic pumps, let's dig into where each type really shines. They're put to work in various industries, adapting to the specific needs of each.

Centrifugal Pump Applications

- Liquefied Natural Gas (LNG) Facilities: Centrifugal cryogenic pumps play a crucial role in turning natural gas into a liquid form for easier transport.

- Medical Equipment: These pumps help cool down MRI machines, making sure we get clear and detailed medical scans.

- Cryogenic Storage: They're essential for keeping biological samples and tissues super cold, which is crucial for research and medical purposes.

Positive Displacement Pump Applications

- Aerospace: Positive displacement cryogenic pumps are a big deal in rocket propulsion, where precision and reliability are everything.

- Labs: They're used in labs to carefully move super cold fluids for scientific experiments.

- Energy Industry: In the energy world, these pumps handle cryogenic fuels like liquid hydrogen and oxygen, and they do it really well.

Types of Cryogenic Pumps and Their Applications

| Pump Type | Main Characteristics | Common Applications |

| Centrifugal Pump | High-flow, low-pressure | LNG plants, medical imaging, cryogenic storage |

| Positive Displacement Pump | Precise control, high-pressure, reliable | Aerospace, laboratories, energy industry |

Key Applications of Cryogenic Pumps

- Medical: Cryogenic pumps have a crucial role in the medical field, where precision and reliability are absolutely essential.

- Aerospace: When we think about exploring space, cryogenic pumps are the unsung heroes that make rocket propulsion possible.

- Energy: The energy industry depends significantly on the power of cryogenic pumps, especially in the production of liquefied natural gas (LNG).

Are There Safety Concerns Associated with Cryogenic Pumps?

It's crucial to recognize that using cryogenic pumps involves particular safety measures. Let's pause for a moment to review essential safety guidelines and precautions to guarantee the secure use of these pumps.

Protective Gear

When working with extremely cold cryogenic fluids, it's essential to wear the right gear for your safety. This means insulated gloves, a face shield, and suitable clothing to stay warm and protect against any splashes.

Ventilation and Containment

Cryogenic fluids may emit potentially harmful gases when they transition into vapor. To avoid the buildup of these gases, it's crucial to ensure proper workplace ventilation and containment systems.

Avoidance of Oxygen-Enriched Atmospheres

Additionally, these fluids can replace oxygen, leading to areas with lower oxygen levels. Workers should receive training to identify and stay clear of enclosed spaces where such oxygen displacement could occur.

Importance of Training

Proper training is essential for ensuring safety while handling these pumps. Insufficient training can be risky for both seasoned professionals and newcomers. Emphasizing the significance of thorough training programs that encompass the safe use, operation, and upkeep of cryogenic pump systems is crucial.

Conclusion

In simple terms, cryogenic pumps are special devices for very cold places. They're important in fields like medicine, aerospace, and energy. They can work in two ways and do various jobs.

For safety, always use protective gear, get proper training, and follow safety rules. Ignoring safety can make cryogenic pumps risky.

In the world of technology, cryogenic pumps connect innovation and opportunity.